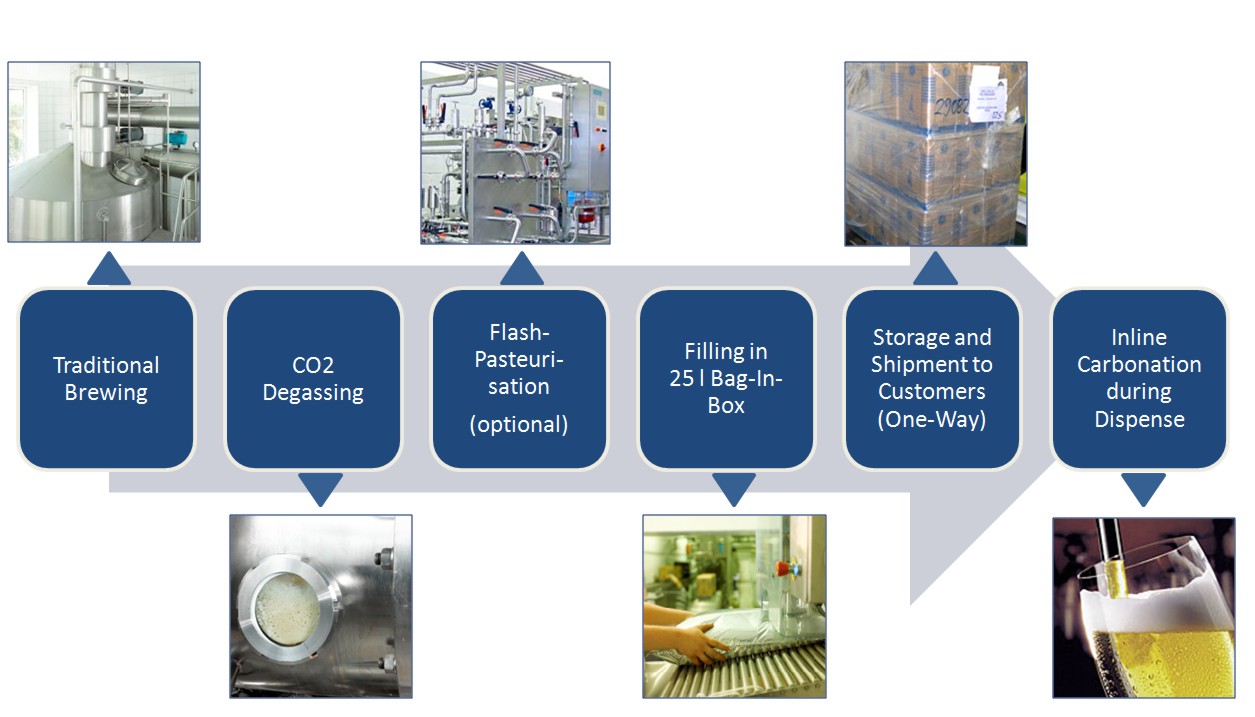

Process principle

The principle concept is as easy and simple as you can imagine: Reducing the CO2 level of the beer prior filling it into bag-in-box packaging and then re-carbonate the beer inline during dispense.

1. Traditional Brewing – The beer is brewed in the traditional way.

2. CO2 Degassing – During this step, the CO2 level of the beer is reduced through a vacuum or hollow fibre based system down to 1g CO2/l.

3. Pasteurization – This optional step guarantees the quality in terms of potential micro influences. As beer-in-box beers are shipped long distances quite often we believe that 100% product quality and security is required. Alternatively micro filtration can be applied on filtered beers.

4. Bag-Filling and Packaging – Depending on the production volume, this step is semi- or fully-automatic. The ultraclean or even aseptic filling technology protects the beer from potential contamination. The high oxygen barrier of the bags contributes to a long shelf life. The filled 25l bags are carried from robust cardboard boxes, that offer great possibilities for attractive designs and visuals. The boxes then get stacked and wrapped onto pallets with a cost saving packaging density.

5. Storage and Shipment – Depending on the defined supply chain, the pallets get shipped to the final destination (unrefrigerated) either directly or through distributors and dealers. The cost and effort for return transport and packaging deposit are eliminated.

6. Inline Carbonation during Dispense – During the dispensing process at the bar or restaurant, the Carbo-Box adds the defined amount of CO2 to the beer. Any existing dispense installation can be upgraded to handle beer-in-box beers this way. For larger installations, the beer boxes can also be connected vertical in series.